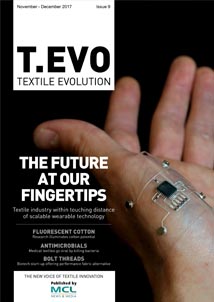

DALLAS — US and Australian researchers have put a new twist on textile spinning to help develop a new class of ‘artificial muscles’ made from highly twisted fibres ranging from carbon nanotubes to nylon threads. Potential applications for the new range of fibres is said to range from range from robotics and prosthetics, to consumer products such as smart textiles that change their shape and structure in response to changes in temperature.

The news comes on the back of previous work by the same research teams at The University of Texas at Dallas, which in 2009 developed artificial muscles made from carbon nanotube aerogel sheets made by a novel solid-state process. This ‘muscle’ is said to be able to operate at extreme temperatures where no other artificial muscle can be used – from below the temperature of liquid nitrogen (-196°C) to above the melting point of iron (1538°C). Once actuated (or put into motion) in a certain direction, these new artificial muscles can elongate 10 times more than natural muscles and at rates 1,000 times higher than a natural muscle.

Now though, through a collaboration between research teams at The University of Texas at Dallas and the University of Wollongong in Australia a new yarn variant of this actuating muscle yarns that means these structures can now be woven, sewn and knitted into a variety of textiles and clothing.