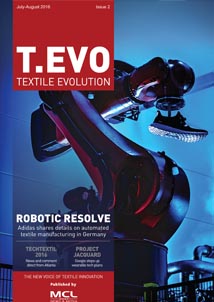

T.EVO was invited to the adidas Group headquarters in Germany to discover more about its innovative approach to technical fabric development and what it considers to be some of the textile industry's biggest challenges when it comes to product design and production. John Mowbray reports from Germany.

After a whirlwind tour of the adidas headquarters in Herzogenaurach, which included stops at its own sports stadium, a gym, the adidas product exhibition and its impressive archive of rare, original gear some of it worn by sports legends such as Muhammed Ali, Franz Beckenbauer and Ed Moses, it was even more clear that speed and efficiency have always been part of the DNA of the global sportswear giant.

Speed and the pace of movement are also evident in the rate of innovation at adidas when it comes to product design. Steve Richardson, Director Materials Sustainability & Innovation gave T.EVO a tour of adidas fabric development lab in its famous ‘Laces’ building where thousands of fabric swatches are analysed, sifted and then selected for its latest sportswear collections.

“In the last few years, our apparel product innovation has focused on temperature regulation working with suppliers such as Toray, Polartec and Invista to go deeper up the supply chain to find new answers to improve garment performance. Knowing what’s happening at the finishing and even the polymer level for synthetic yarns is becoming more critical,” said Richardson, adding: “Function and comfort for our athletes and consumers are always our top considerations. Durability, sustainability, and feel support functionality, but our focus is on improving the experience for our athletes and consumers.”

Asked how textile industry suppliers can help adidas to reach these goals, he noted: “We want to work with T2 and T3 suppliers to develop authentic technologies that can help our athletes and consumers perform better, and have a better experience. We need to engage early so we have time to validate the functionality and apply it in the correct manner and we need access to sample yardage so we can get garments on the field with our athletes.”

A single technical example of one technical hurdle that is being worked on relates to adidas’s commitment to phase out the use of fluorocarbon-based (PFC) water repellent in its supply chains and expects to be 99 per cent PFC-free by no later than December 31, 2017 due to environmental concerns.

“But we don't just use fluoro-chemistry for water repellency, in some instances we use PFC’s to stop colour migration from fabrics on to the adidas stripes,” said Richardson, “We need to understand how we can prevent this effectively without the use of PFCs.”

It’s clear, that adidas is looking at manufacturing efficiencies, getting better lead times and therefore being closer to consumers, which it is why the company is supporting the ‘Speedfactory’ project supported by the German government. But what is this?

In a nutshell, Silvia Raccagni, Corporate Communication at adidas told us: “Under the umbrella of Speedfactory, it is our goal to develop new products with new, intelligent technologies and to manufacture these products in an automated and flexible manner. This will enable us to produce closer to the consumers and to fulfil their demand for customised and personalised products on the spot.

“The strong linking of Information and Communication Technologies (ICT) with the industry implies significant growth potential. ICT technologies will revolutionise the industrial production over the coming decades. Therefore, it is crucial to set the course early on … New technologies always unlock new opportunities. We are convinced that new ways of manufacturing will offer additional solutions and strengthen the production portfolio of the adidas Group to generate competitive advantage.

“It is important to us to be at the forefront of innovation and technology across all categories, in order to continue to provide our consumers with disruptive products and features in a sustainable manner.”

Speedfactory kicked off as a research project in October 2013 and is planned to run for three years, until the end of September 2016.

Near field communication

At point of sale and beyond, adidas is also looking to the textile manufacturing supply chain to provide answers to how it can keep track of consumer purchasers.

Like some retailers, adidas is said to be building near field communications (NFC) into its footwear, apparel and sporting equipment in the hope of triggering millions of consumer touch points it can use to keep talking to people long after they’ve made a purchase.

Like most brands, adidas does not know exactly who buys its products (unless purchase direct), and is trying to solve this problem by creating products such as football boots and clothing that are ‘wearable technology’.

Speaking at the South by Southwest conference in March 2015 in Texas, Jon Warner, innovation specialist at Adidas, revealed a decision to stitch NFC (near field communication) technology into its products in a bid to generate more information on where and how people are using adidas gear so that it can more accurately predict trends for its marketing and production teams.

NFC technology enables smartphones (not yet Apple) and other devices (that may be embedded in clothing) to establish radio communication with each other via the cloud.

“It’s through an ability to understand what they’re doing, the type of runner they are and how often they tap their products that we can start to learn more about how they are being used,” Warner explained, “We won’t recommend them sweaters if they’re in the south and its warm and we can actually start to be very specific about how we reach them.”

Back in Herzogenaurach adidas is exploring how NFC could be weaved into fabrics, but it will not go into specifics and does not generally talk about its projects on wearable textiles. Unlike footwear, we understand adidas is not yet ready to launch anything with development still in the conceptual stage. Although we know one such prospect is a football shirt that could serve up team information or statistics of a specific player when the logo is tapped.

Just as speed is an integral part of the adidas DNA, it’s clear that collaboration and sustainability are also a growing part of its genetic make-up when it comes to technical fabric development.